More information

Alloy 1555 is a non-heat-treatable Al-Mg alloy, providing greater strength than alloy 5182, without loss of ductility. It contains 0.02% Sc.

A typical application is high strength automotive deep drawn inner stampings.

The new 7xxx series high-strength alloy with low scandium content is specifically designed for manufacturing forged wheels.

The new 7xxx series high-strength alloy with low scandium content is specifically designed for manufacturing forged wheels.

Products

Slabs

Billets

Benefits

Alloy 1555

Improved strength-to-weight ratio of a structure

+ 16 %*

Enhanced yield strength

+ 29 %*

Reduction in structure weight

* compared to commercial alloy 5182

up to

-

10 %*

Guaranteed mechanical properties of sheets from alloy 1555

Temper

Thickness, mm

Mechanical properties

UTS, MPa

YS, MPa

El, %

O / H112

All thicknesses

300

155

22

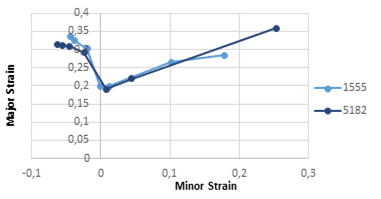

Formability and corrosion resistance are comparable to those of alloy 5182-O

Form Limit Curve (1555 & 5182)

7xxx series high-strength alloy for forged wheels

Forged wheel ****

Yield strength

≥ 430 MPa

** the typical yield strength for alloy 7075-T73

is 410 MPa

is 410 MPa

Reduction in weight

15-18%

*** compared to forged wheels made from alloy 6061

Source: https://powerwheels.ru

**** the image is for informational purposes only.

RUSAL’s Products

Al-Sc продукт

Slabs

Billets

Wire rod

Powder, 3D printing

Foil

1ХХХ

-

-

-

-

-

5ХХХ

yes

-

-

-

-

7ХХХ

-

yes

-

-

-

8ХХХ

-

-

-

-

-

The products meet the requirements of Russian and international standards, as well as customer specifications.

Contacts:

Aleksandr Krokhin,

Head of Department of Casting Technology and New Product Development

tel.: +7 (495) 720-51-70

Irina Gavrilova,

Head of Sales Department, Russia and the CIS countries

tel.: +7 (495) 720-51-70