More information

Alloy RS-553 is a high-strength, corrosion-resistant aluminum alloy designed for additive manufacturing (AM). Its key advantage is the achievement of peak performance through an annealing process, without quenching. RS-553 parts are fully weldable and machinable using standard methods for conventional Al-Mg alloys.

In combination with innovative AM-design, this material enables significant weight reduction, material savings, and superior mechanical performance for end-use components.

In combination with innovative AM-design, this material enables significant weight reduction, material savings, and superior mechanical performance for end-use components.

Products

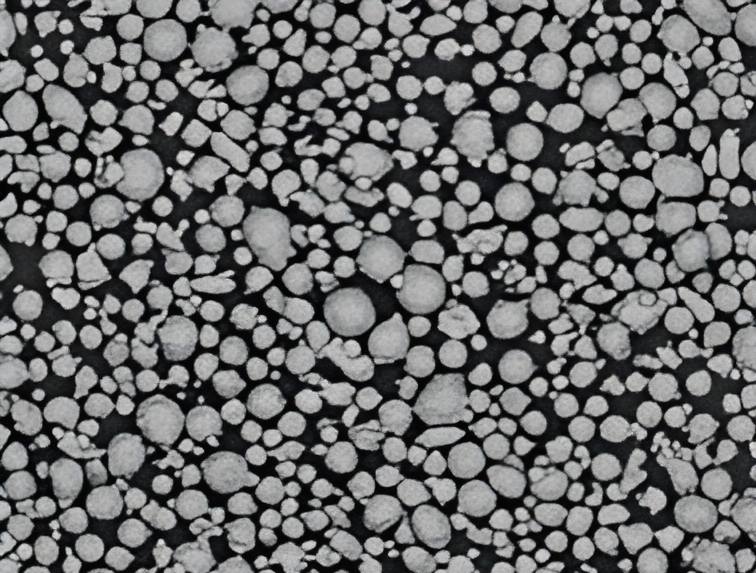

Powder 3D printing

Benefits

Tensile strength

+30%*

Yield strength

+85%*

Elongation

+75%*

* compared to commercial equivalent alloy AlSi10Mg (RS-300)

Material density, g/cm3

2,65

Porosity of AM product, %

≤ 0,4

Guaranteed mechanical properties of alloy RS-553

Process

Direction

Tensile properties

UTS, MPa

YS, MPa

EL, MPa

E, GPa

As-printed

XY

390

290

25,0

72

Z

380

290

22,0

Annealing

XY

470

435

14,1

69

Z

460

430

15,0

Direction

Fatigue strength at cycles (σ-1), MPa

Corrosion properties

Corrosion rate, mg/m2·day

Corrosion rate, mg/m2·day

Conditions

20°С, N = 1 ·107, ν = 300 Hz, R = -1

Without HT

Annealing at 150°C

for 50 h

Annealing at 100°C

for 100 h

XY

100

65

87

39

Z

99

38

229

116

High resistance to Intergranular and exfoliation corrosion

Implemented solutions

Powder

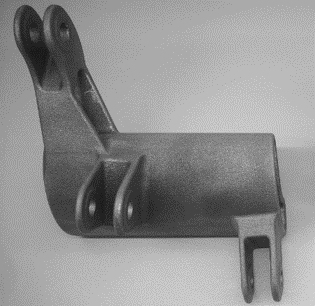

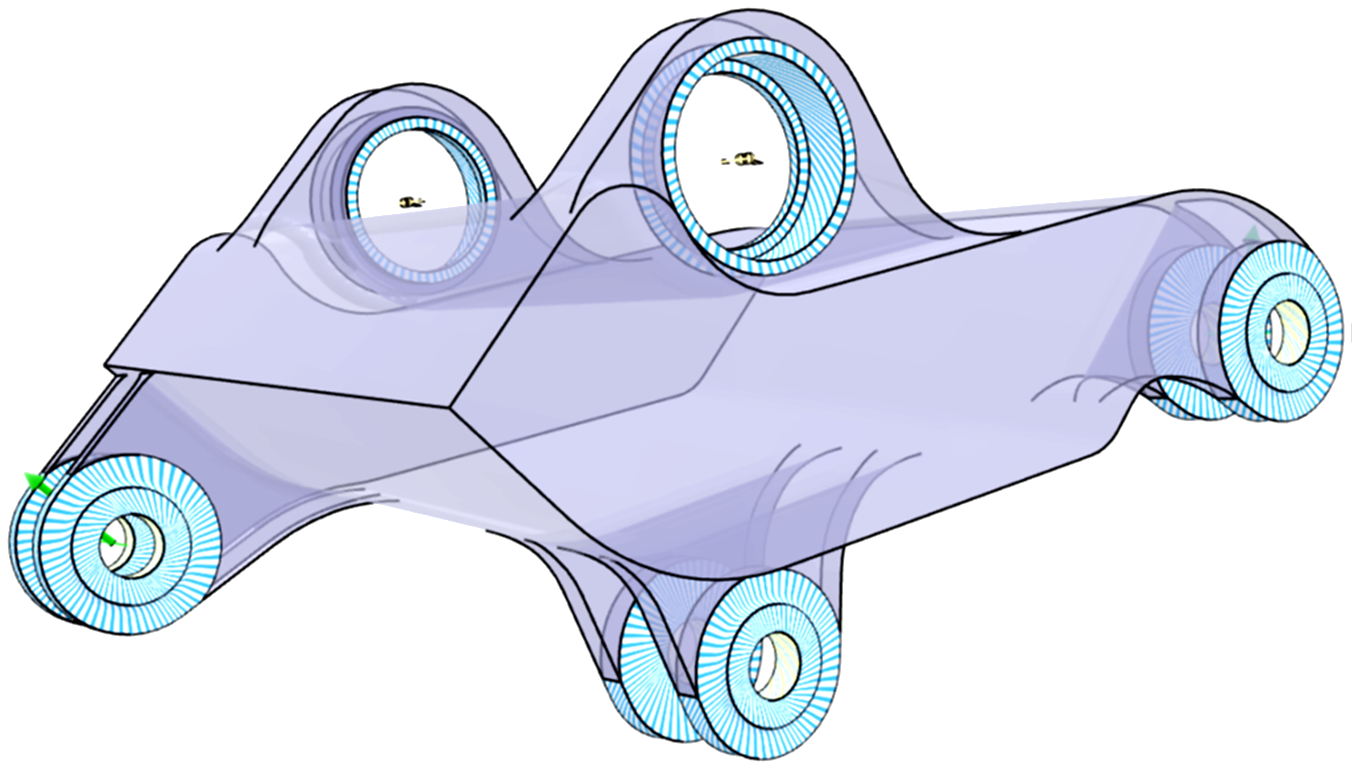

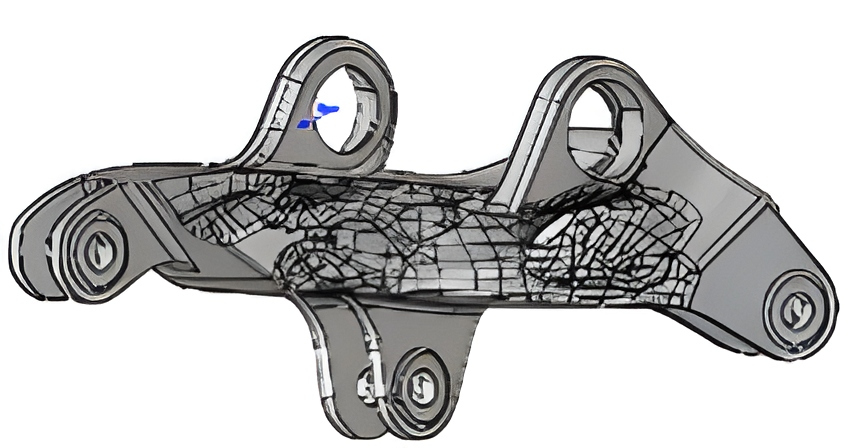

Test pieces

AK7ch (casting) Weight: 641 g

RS-553 (3D printing) Weight: 370 g (-42%)

Topology optimisation

RUSAL’s Products

Al-Sc product

Slabs

Billets

Wire rod

Powder, 3D printing

Foil

1ХХХ

-

-

-

-

-

5ХХХ

-

-

-

yes

-

7ХХХ

-

-

-

-

-

8ХХХ

-

-

-

-

-

The products meet the requirements of Russian and international standards, as well as customer specifications.

Contacts: